The MUTCD’s requirements for maintaining traffic sign retroreflectivity have a big impact on the kind of sign you should buy. Here’s what you need to know.

Traffic signs are designed so that all drivers, no matter what language they speak, can understand their guidelines and warning symbols. But traffic signs, of course, don’t work unless you can see them. In the early days of horseless carriages, night driving was a gamble because no one could make out the words on the signs. As a result, in 1932, standard shapes were adopted for different types of signs, so words wouldn’t always be necessary. Soon, drivers understood what a sign meant just by glimpsing its outline in the moonlight and were alerted to avoid danger.

Traffic sign regulations have come a long way since then, as they had to adjust to increased traffic, higher speeds, and dangerous weather conditions. The Federal Highway Administration (FHWA) updates these regulations as needed in its Manual on Uniform Traffic Control Devices (MUTCD), and it’s part of our job at Custom Products Corporation to stay on top of them. That way, we can recommend the best materials for signs that need to be highly visible in all locations and conditions.

The MUTCD’s requirements for maintaining traffic sign retroreflectivity are the best way to ensure that drivers can see the signs—and avoid accidents. “Retroreflectivity” refers to a sign’s ability to reflect an automobile’s lights back at the driver, calling attention to the sign. Technology has improved visibility with “reflective sheeting,” a smooth, sealed outer surface featuring miniature glass beads or microprismatic lenses.

Over time, signs and their reflective surfaces degrade because of the weather and sun exposure. But drivers need these signs in top condition because the nighttime crash rate is nearly three times that of the daytime rate. The MUTCD has established minimum standards for a sign’s retroreflectivity, with mathematical guidelines for many variables. As any signs are replaced or refurbished, they need to be updated to the most recent retroreflectivity standard for that sign type. We refer to a table with formulas to assess the minimum requirements for a sign, taking into account where and how it’s mounted, the sign’s colors, which sheeting is used, and more.

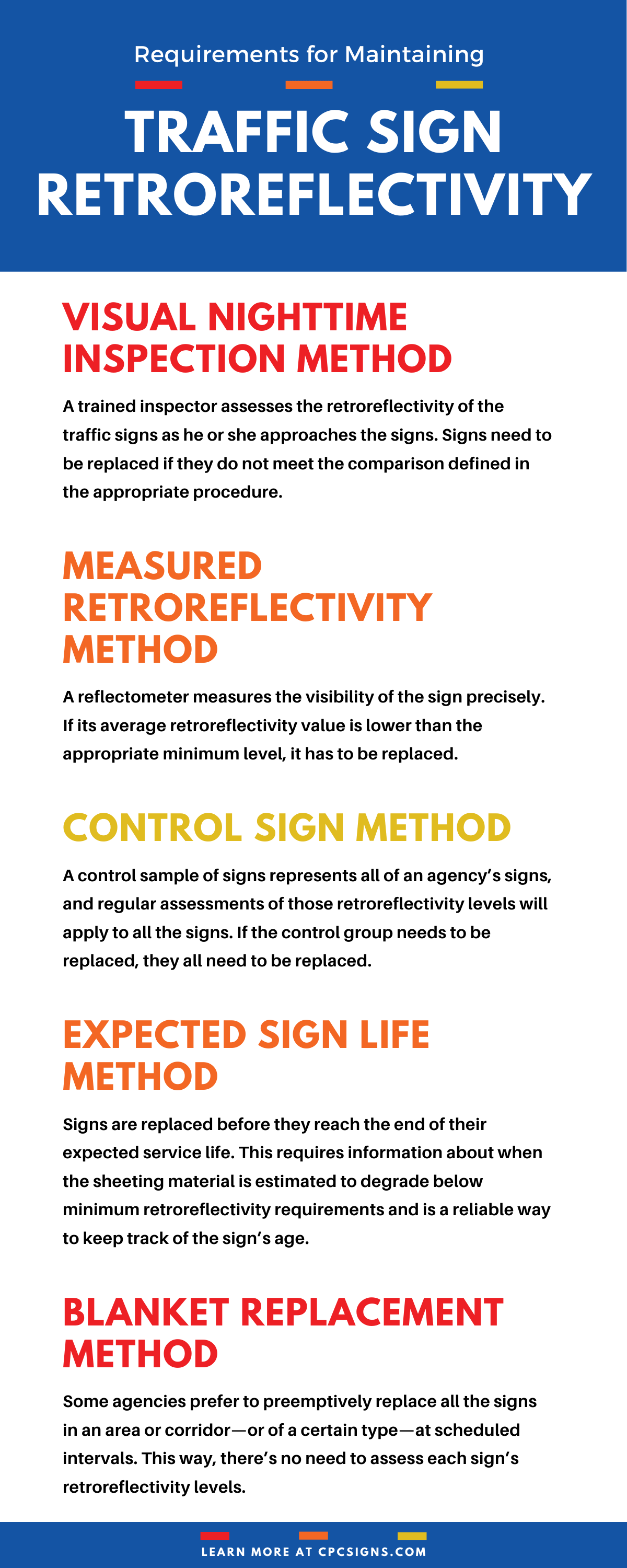

The tool for measuring reflectivity is called—you guessed it—a reflectometer, but that’s not the only way to ensure a sign is compliant with the FHWA. Agencies are required to have a program with regular assessments of reflectivity, and the FHWA offers five methods you can use. As long as signs are being regularly inspected by one of these methods, they are compliant.

Visual Nighttime Inspection Method

A trained inspector assesses the retroreflectivity of the traffic signs as he or she approaches the signs. Signs need to be replaced if they do not meet the comparison defined in the appropriate procedure.

Measured Retroreflectivity Method

A reflectometer measures the visibility of the sign precisely. If its average retroreflectivity value is lower than the appropriate minimum level, it has to be replaced.

Control Sign Method

A control sample of signs represents all of an agency’s signs, and regular assessments of those retroreflectivity levels will apply to all the signs. If the control group needs to be replaced, they all need to be replaced.

Expected Sign Life Method

Signs are replaced before they reach the end of their expected service life. This requires information about when the sheeting material is estimated to degrade below minimum retroreflectivity requirements and is a reliable way to keep track of the sign’s age.

Blanket Replacement Method

Some agencies prefer to preemptively replace all the signs in an area or corridor—or of a certain type—at scheduled intervals. This way, there’s no need to assess each sign’s retroreflectivity levels.

The MUTCD is open to other methods, too, as they are developed and based on engineering studies. It’s not easy to establish uniformity of all traffic control devices, especially when so many factors can affect a sign’s brightness. It can vary depending on road conditions, vehicle and driver type, the position of both the sign and the vehicle, and more.

These retroreflectivity levels are increasing in importance, as there’s a need for signs to be brighter than ever. New vehicle technology, increased urbanization, larger vehicles, and a greater number of older drivers are just a few reasons to invest in the best reflective sheeting that’s appropriate for your signs. At Custom Products Corporation, we’ve learned which sheeting has the best track record and visibility, and we prefer to use them when making our custom safety signs. We tell clients that they can depend on 3M’s High-Intensity Prismatic, VIP Diamond Grade, or Diamond Grade Cube sheeting for the brightest signs. For instance, a Type I Engineer Grade sheeting offers 7 percent optical efficiency, while 3M’s High-Intensity Prismatic sheeting offers 32 percent. Type 1’s expected life is 7 years, while HIP’s is 10 years.

Upgrading your sign’s sheeting also has many cost advantages.

- You can eliminate yearly evaluation costs by using the Expected Sign Life or Blanket Replacement methods for assessing retroreflectivity—methods that are not authorized for Type I sheeting.

- Type I may need to be replaced up to 2.5 times as often as HIP or DG3.

- Type I does not have a warranty. HIP has a 10-year warranty, and DG3 has a 12-year warranty.

- Higher-quality sheeting reduces lower tort-liability exposure.

Of course, none of that is as important as safety considerations. You’ll need to become familiar with the MUTCD’s requirements for maintaining traffic sign retroreflectivity, but if you choose the safest materials available for your signs, compliance will follow. Overseeing what happens on the roads is a big responsibility. In 2019, an estimated 38,000 people lost their lives in car crashes in the United States, and another 4.4 million were seriously injured. Brighter, longer-lasting traffic signs are a simple, more effective way to make sure that drivers are getting the information that can prevent accidents. Even neglectful and distracted drivers can’t miss a warning sign if it’s glowing like a neon beacon.

Custom Products Corporation can show you the best sign options for nighttime visibility and even save you money at the same time. Contact us for more information on how we can help you keep our roads safe.