When you’re responsible for ordering the signs that keep your streets safe, you’ll need digitally printed traffic sign guidance to ensure the best results.

Drivers pass traffic signs all the time without much thought, but that doesn’t make signs any less crucial. They save lives every day, and their visibility needs to be held to the highest standards. When you’re responsible for installing and replacing digitally printed traffic signs, you’ll need guidance on the specific requirements for your situation. The American Traffic Safety Services Association is the best source for standards, in conjunction with the American Society for Testing and Materials.

The Need for Standards

In the early days of “horseless carriages,” the few vehicles on the road were required to drive behind a pedestrian who waved a red flag or carried a lantern to warn bystanders. As more cars took to the road, that became less practical. Directional signs and danger warnings sprang up, but they all looked different and were nearly impossible to see at night and in bad weather conditions.

We take traffic signs for granted, but it took an enormous effort in 1932 to coordinate shapes, colors, and symbols that would be immediately recognizable across the country and in any language. Regular maintenance helped decrease signs that were damaged, concealed by vegetation, bent, or missing entirely. Streetlights made it possible to see signs in low light, and technology added to their brightness.

Today, the effectiveness of traffic signs are measured in a variety of ways, from “retroreflectometers” to mobile eye-tracking glasses on drivers. There’s no way of knowing how many accidents traffic signs prevent, but signs alone are not enough. In 2019, an estimated 38,000 people died in crashes in the United States. The simple fact is that traffic signs don’t work if drivers don’t see them. And the best sign visibility begins at manufacture. Here’s what you need to know to ensure the most effectiveness, for digitally printed sign faces and retroreflective traffic signs manufactured on flat sheet aluminum.

Ink Systems

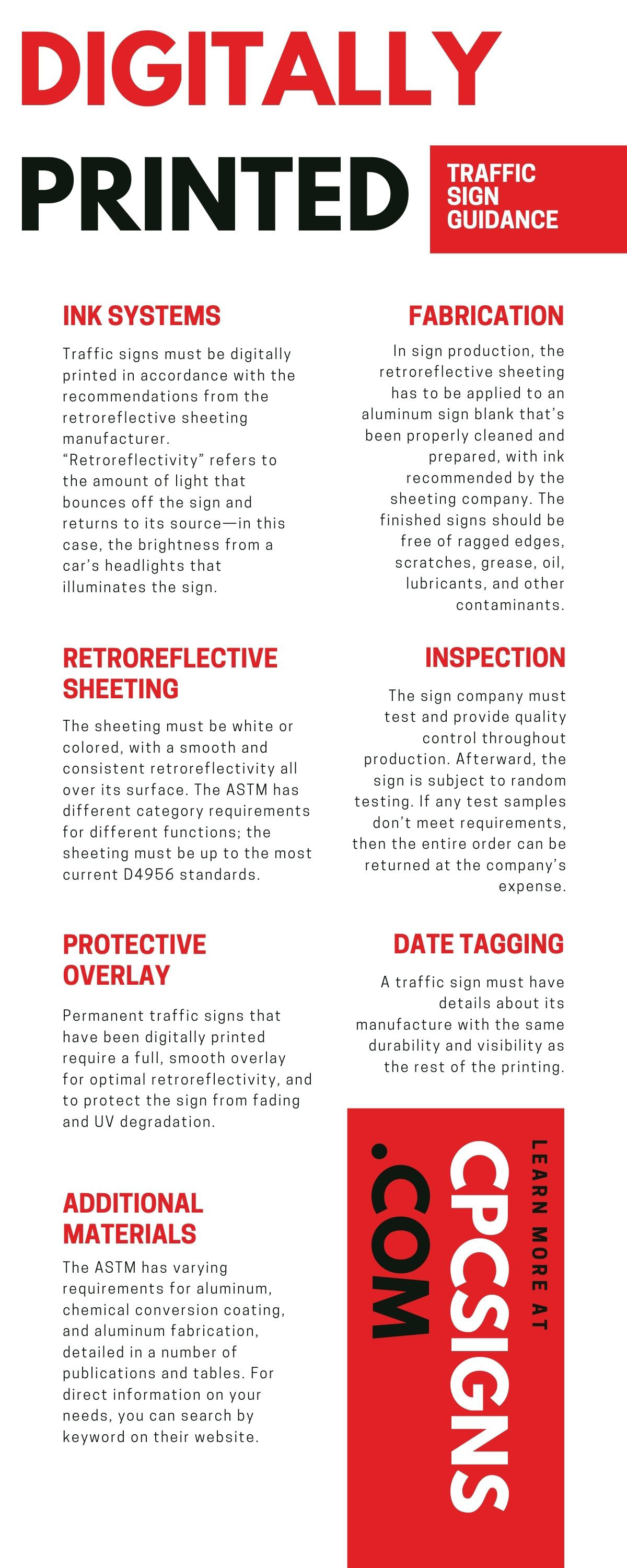

Traffic signs must be digitally printed in accordance with the recommendations from the retroreflective sheeting manufacturer. “Retroreflectivity” refers to the amount of light that bounces off the sign and returns to its source—in this case, the brightness from a car’s headlights that illuminates the sign. The retroreflectivity of traffic signs has increased along with advances in technology.

The ink for traffic signs also needs to comply with daytime and nighttime chromaticity (color standards). Each color of ink used on the signs has to meet 70 percent of the initial retroreflectivity specifications according to the ASTM. Custom Products Corporation can help you determine the standards for your needs.

Retroreflective Sheeting

The sheeting must be white or colored, with a smooth and consistent retroreflectivity all over its surface. The ASTM has different category requirements for different functions; the sheeting must be up to the most current D4956 standards. The sheeting must also have a Class 1 pressure-sensitive adhesive, protected by an easily removable liner.

Protective Overlay

Permanent traffic signs that have been digitally printed require a full, smooth overlay for optimal retroreflectivity, and to protect the sign from fading and UV degradation. The overlaminate must conform to the sheeting manufacturer’s recommendations for transparency, adhesion, and durability. (Temporary signs printed with black ink only will not require a protective overlay, as long as the finished sign is warranted for a minimum of three years of outdoor durability.)

Additional Materials

The ASTM has varying requirements for aluminum, chemical conversion coating, and aluminum fabrication, detailed in a number of publications and tables. For direct information on your needs, you can search by keyword on their website. In addition, the Manual for Uniform Traffic Control Devices (MUTCD) dictates requirements for size, shape, thickness, and weight.

Fabrication

In sign production, the retroreflective sheeting has to be applied to an aluminum sign blank that’s been properly cleaned and prepared, with ink recommended by the sheeting company. The finished signs should be free of ragged edges, scratches, grease, oil, lubricants, and other contaminants. If minor blemishes (dirt speck, dust) are present on the sign from production processes, they must not be visible to the naked eye from 30 feet or more, and they must not affect visibility at any distance. Finished signs must be packaged to prevent damage according to the sheeting company’s recommendations.

Preprinted sign faces must adhere to the recommendations of the reflective sheeting manufacturer as listed above. In addition, the width and length of the sign should have a border between 1/32 and 9/16 of an inch to allow for trimming.

Inspection

The sign company must test and provide quality control throughout production. Afterward, the sign is subject to random testing. If any test samples don’t meet requirements, then the entire order can be returned at the company’s expense.

Warranties

Signs will be warrantied according to the duration of its sheeting material. There may be limitations dependent on ink colors and the geographic location of the sign. The sign company will provide a copy of the warranty document on request, including all details of the terms and conditions.

Manufacturer Certification

The company making the digitally printed signs needs to be certified by the manufacturer that provides the reflective sheeting. The printing company must be audited for the proper equipment, manufacturing capabilities, manufacturing application processes, and materials required by the sheeting company. Sign fabricators must be recertified annually, and provide proof of its status with any purchase order or construction contract.

Custom Products Corporation is a certified manufacturer of 3M materials.

Date Tagging

A traffic sign must have details about its manufacture with the same durability and visibility as the rest of the printing. It must include the name of the manufacturer, the month and year it was produced, the process used in making the sign (screen printing, digital printing, cut vinyl), and the supplier of the sheeting.

Whether you need a street name sign or a serious warning sign, you’ll need the highest quality available. Emergency workers rely on street signs to arrive quickly at a crisis location, and a stop sign can prevent devastating accidents, so quality and adherence to guidelines must always come first.

The traffic environment is becoming more complex and demanding every day, and we need to adapt our standards for signs accordingly. Custom Products Company can provide the digitally printed traffic sign guidance for your specific needs. Contact us for more information.